MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Checking Fluid Level

- With the vehicle on a level surface and the fluid in the transaxle cold, remove the filler plug and check the fluid level. The fluid should come to the bottom edge of the plug hole.

- If the level is low, add SAE75W90 manual transaxle fluid through the filler plug hole until the fluid begins to run out.

- Reinstall the filler plug and tighten it securely.

- If the fluid is contaminated, drain the oil after removing the differential gear cover.

Shift Linkage Adjustment

(Left-Hand Drive shown, Right-Hand Drive Similar)

- Disconnect the negative battery cable.

- Position the gearshift lever into NEUTRAL.

Important : All the gears must be easy to engage when the vehicle is stationary, the engine is running, and the clutch is disengaged.

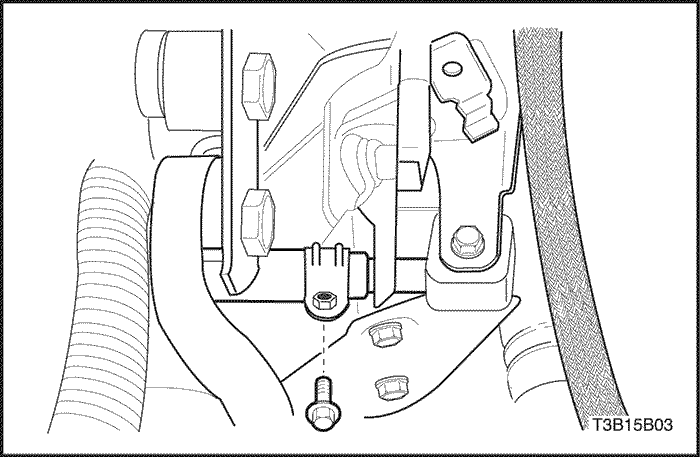

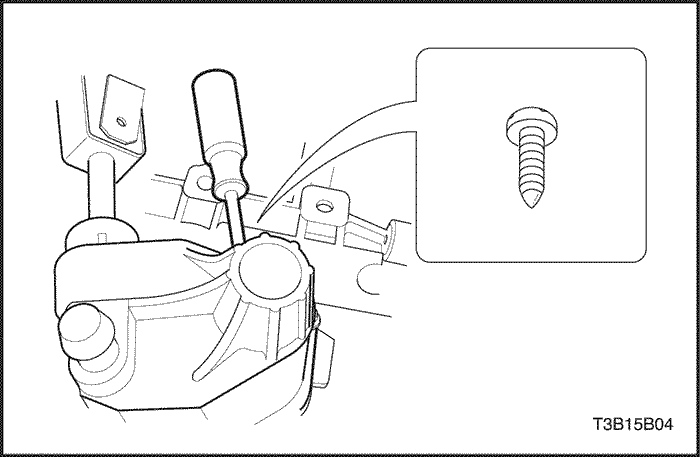

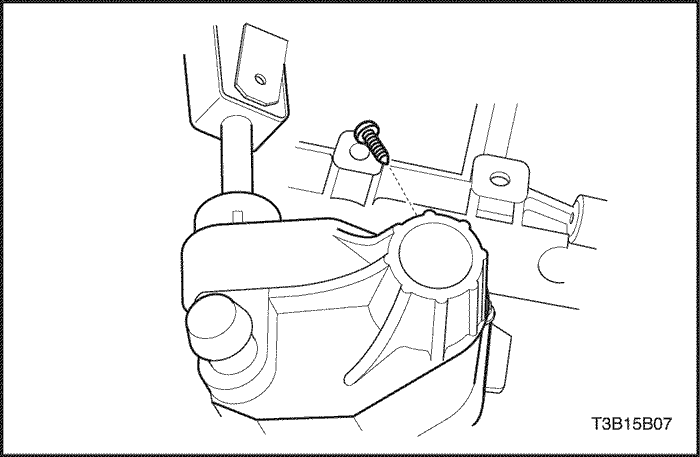

- Loosen the rod clamp bolt.

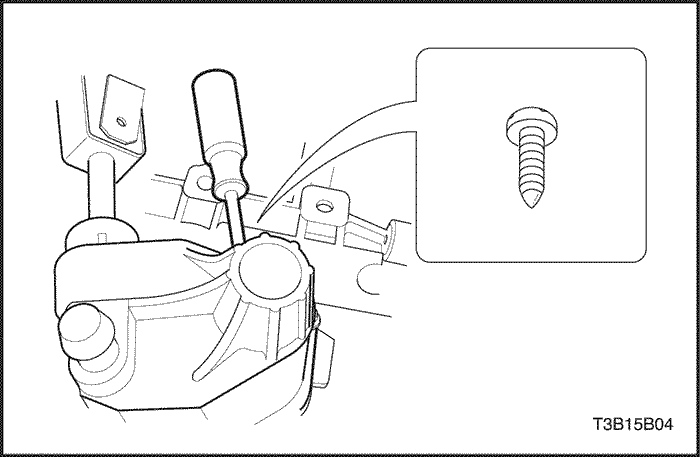

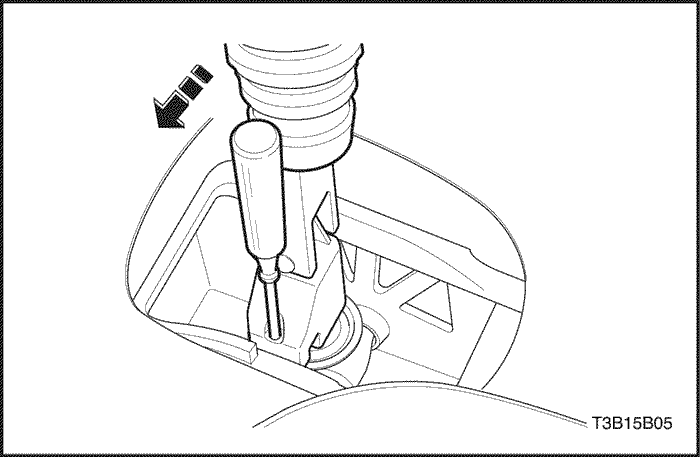

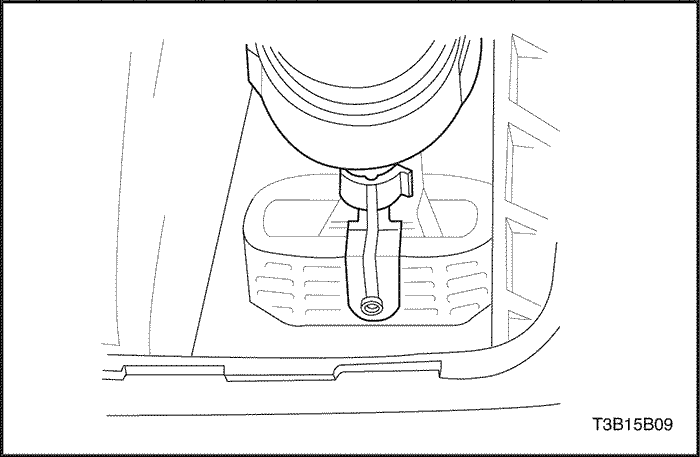

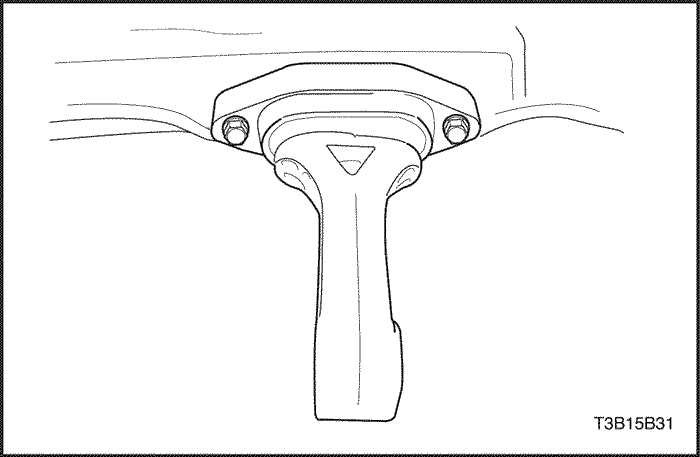

- Remove the adjustment hole plug from the shift lever cover.

- Turn the gearshift rod and fully insert a 5 mm (0.2 inch) gauge pin into the adjustment hole.

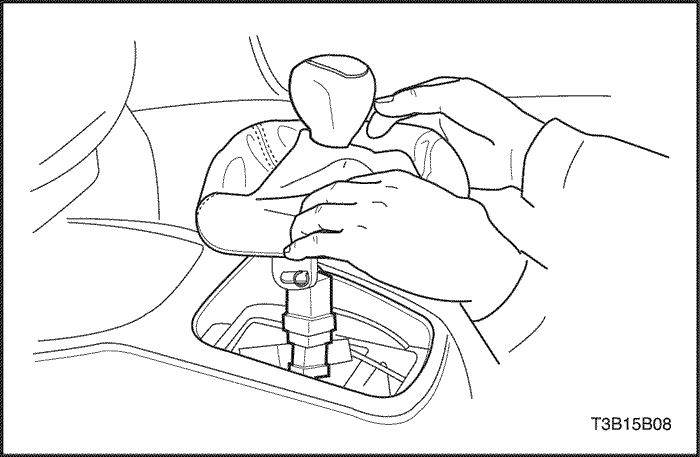

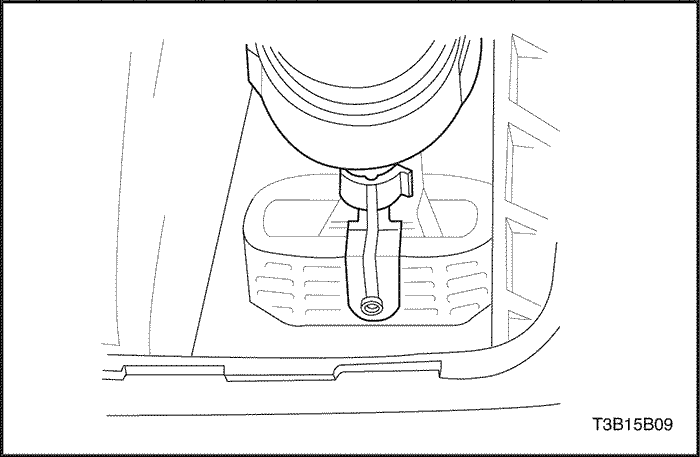

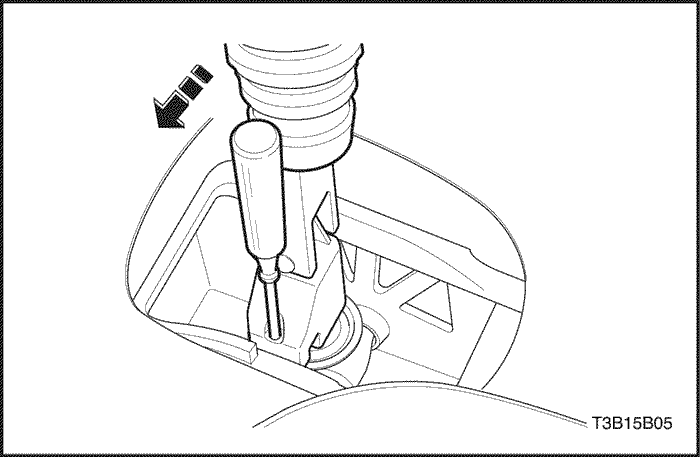

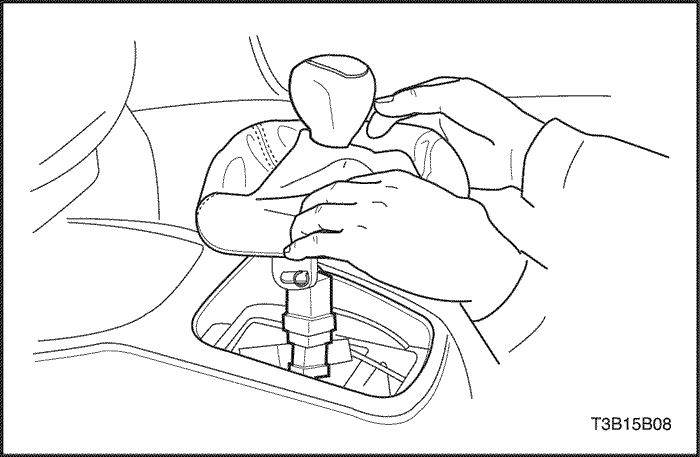

- Remove the boot from the console.

- Pull the boot upward to expose the shift control lever mechanism.

- Position the gearshift lever close to left side of the NEUTRAL position.

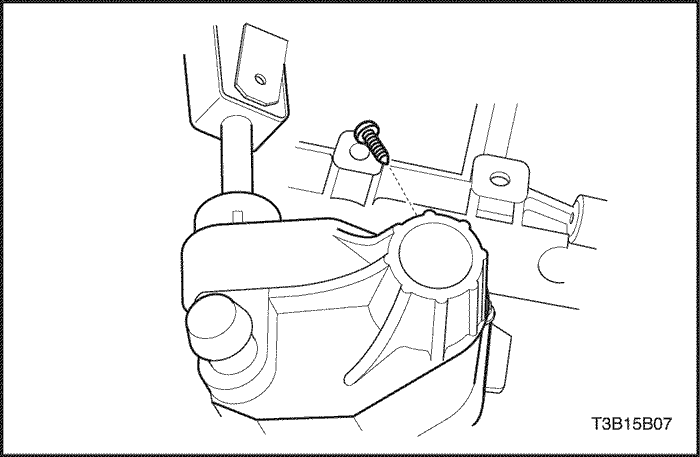

- Insert a 5 mm (0.2 inch) gauge pin into the holes to align the gearshift lever with the gearshift lever housing.

- Tighten the rod clamp bolt.

Tighten

Tighten the rod clamp bolt to 14 N•m (124 lb-in).

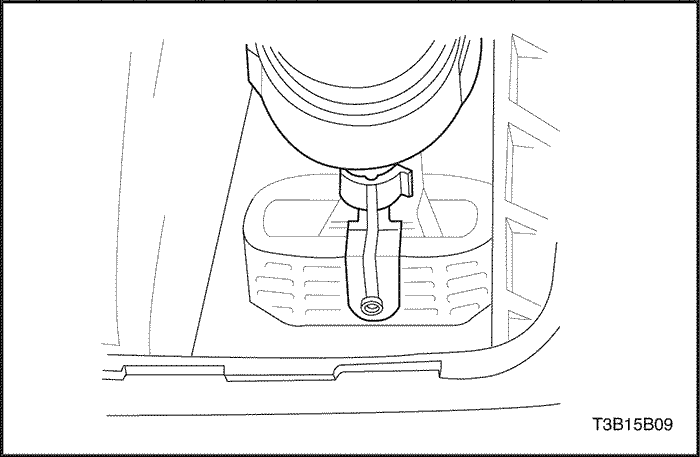

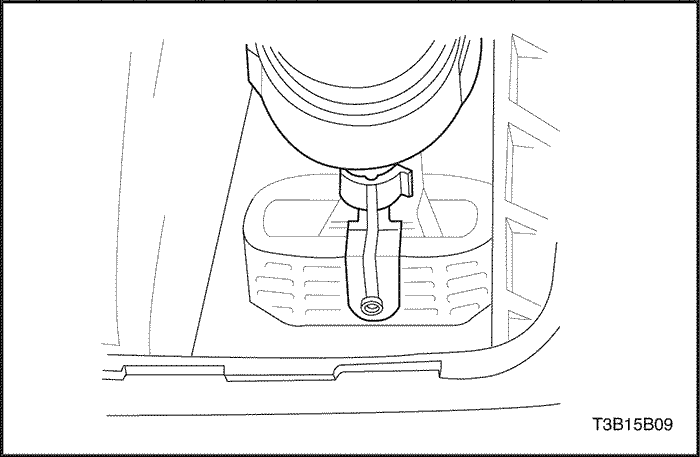

- Remove the 5 mm (0.2 inch) gauge pin from the adjustment hole.

- Install the adjustment hole plug.

- Remove the 5 mm (0.2 inch) gauge pin from the gearshift lever.

- Install the boot to the console.

- Connect the negative battery cable.

Gearshift Lever

(Left-Hand Drive shown, Right-Hand Drive Similar)

Removal Procedure

- Disconnect the negative battery cable.

- Position the gearshift lever into NEUTRAL.

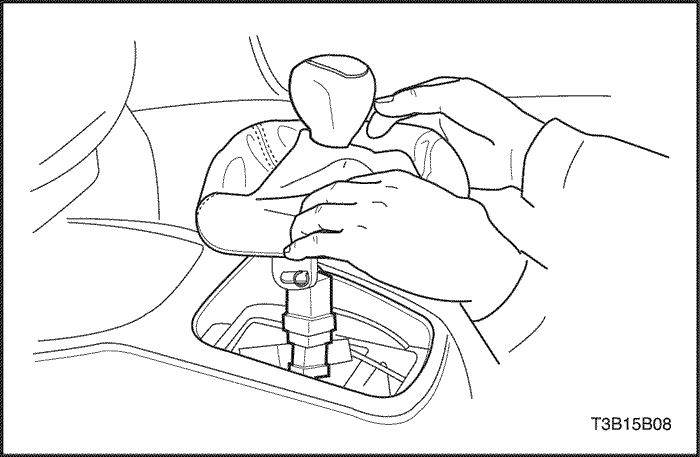

- Disconnect the boot from the console cover.

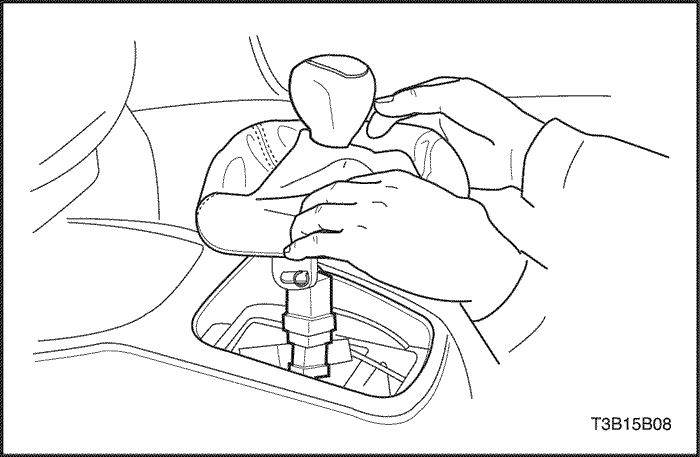

- Lift the console cover upward to expose the shift control lever mechanism.

- Rotate the gearshift lever stop clamp and remove it.

- Remove the gearshift lever from the gearshift lever shaft.

Installation Procedure

- Install the gearshift lever into the gearshift lever shaft.

- Install the gearshift lever stop clamp.

- Rotate the gearshift lever stop clamp to secure it.

- Lower the boot and connect it to the console cover.

- Connect the negative battery cable.

Gearshift Lever Housing

(Left-Hand Drive shown, Right-Hand Drive Similar)

Removal Procedure

- Disconnect the negative battery cable.

- Remove the rod clamp. Refer to "Shift Linkage Adjustment" in this section.

- Remove the console.

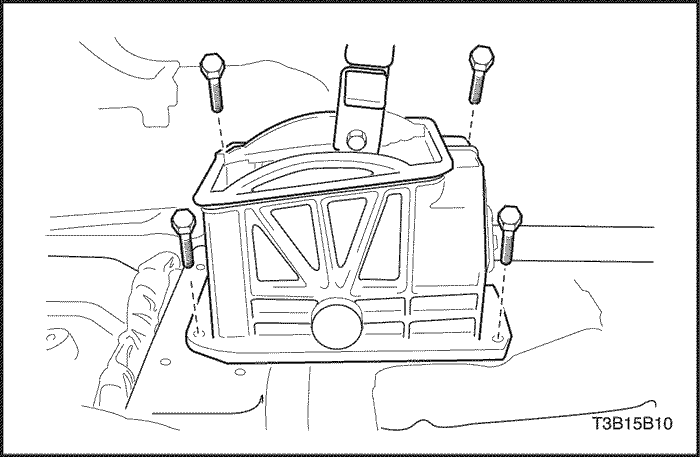

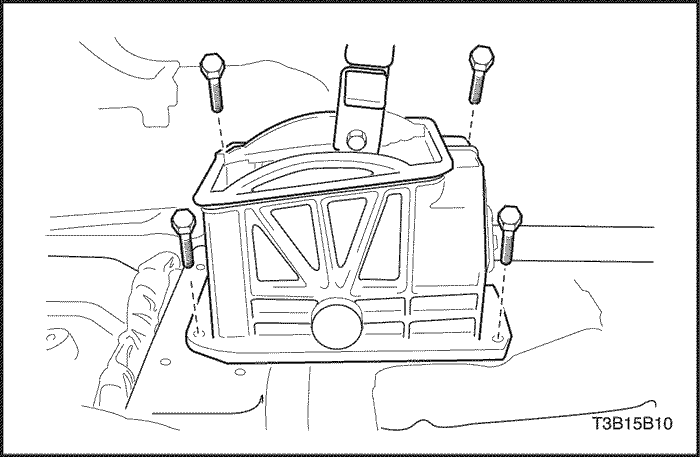

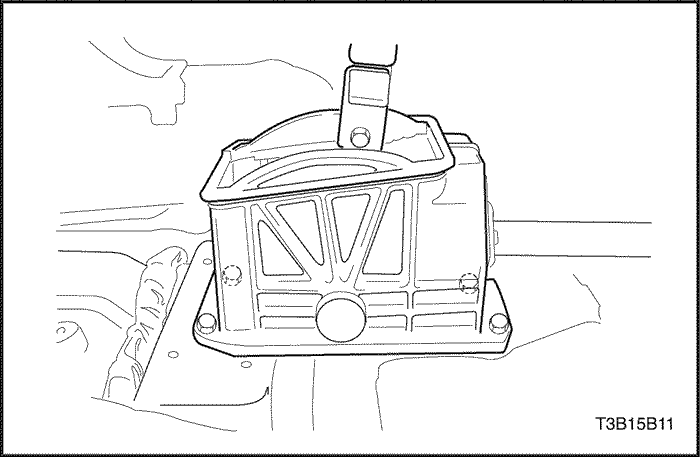

- Remove the gearshift lever housing bolts and the gearshift lever housing.

Installation Procedure

- Install the gearshift lever housing and the gearshift lever housing bolts.

Tighten

Tighten the gearshift housing bolts to 7 N•m ( 62 lb-in).

- Adjust the shift linkage.

- Install the console.

- Connect the negative battery cable.

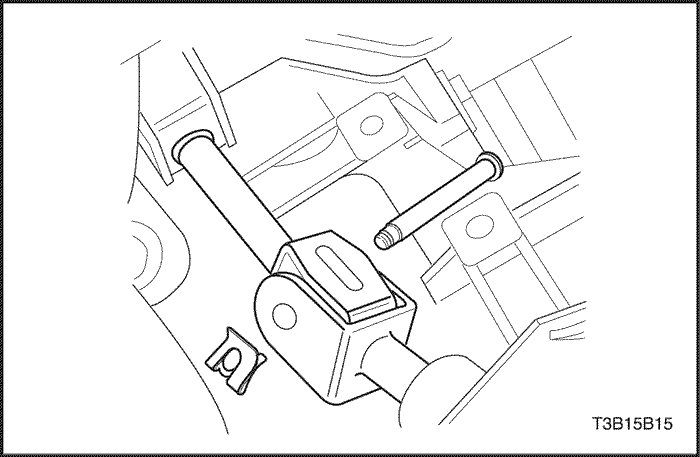

Speedometer Driven Gear

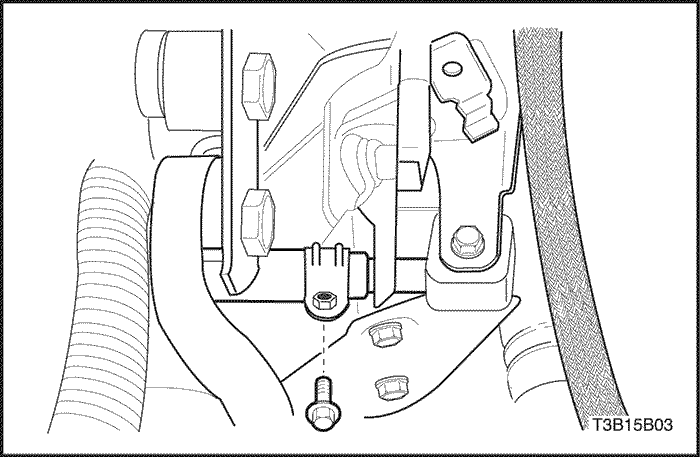

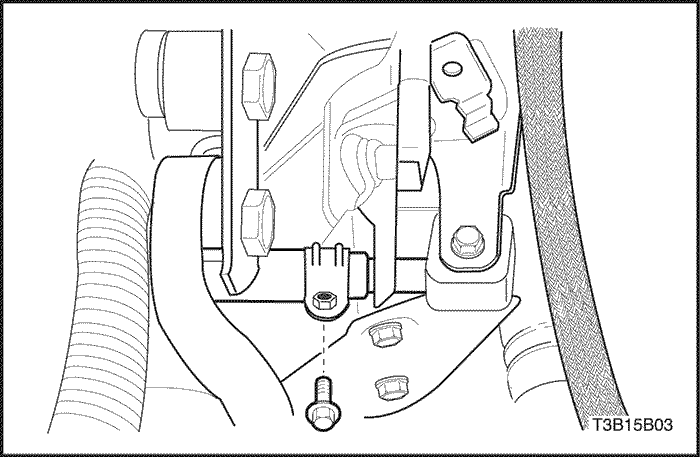

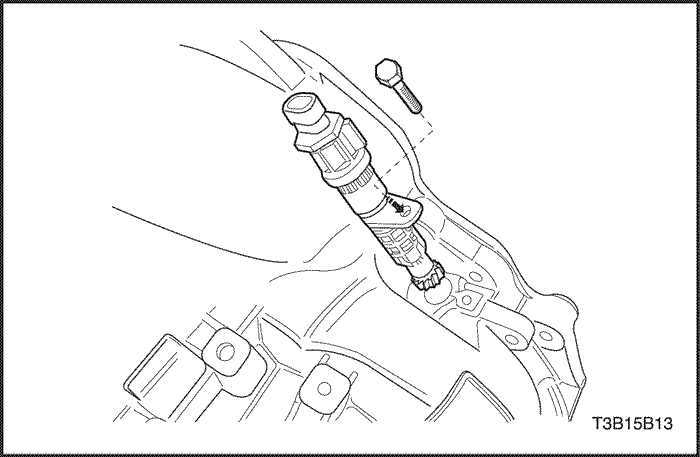

Removal Procedure

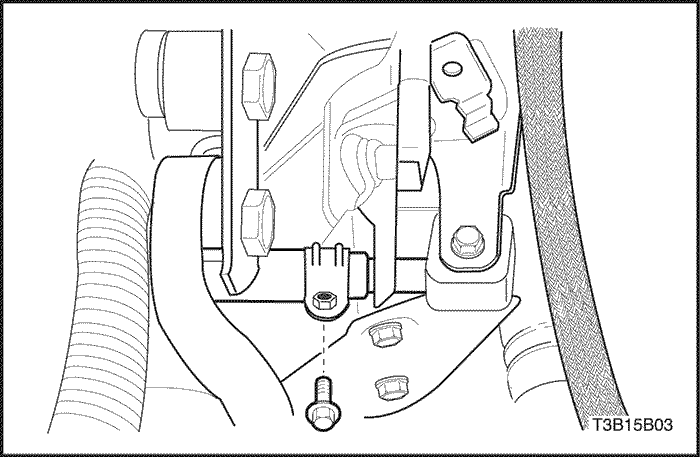

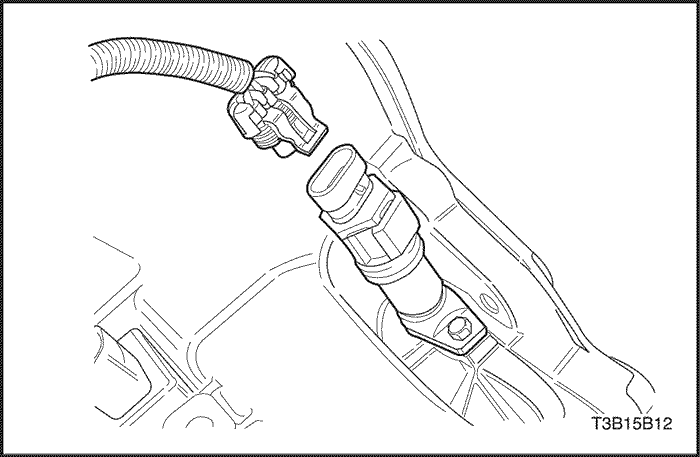

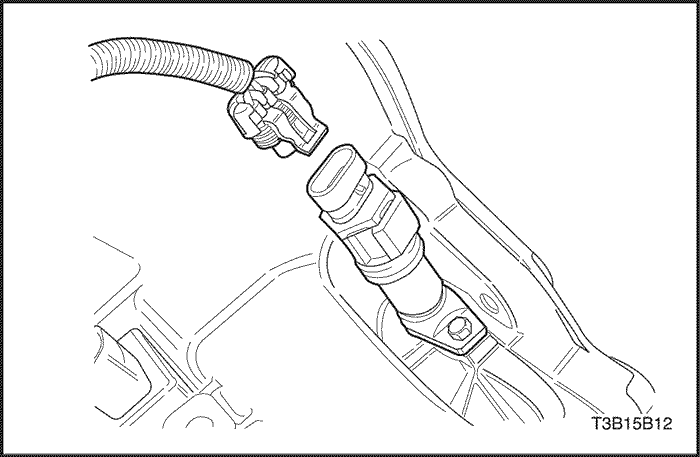

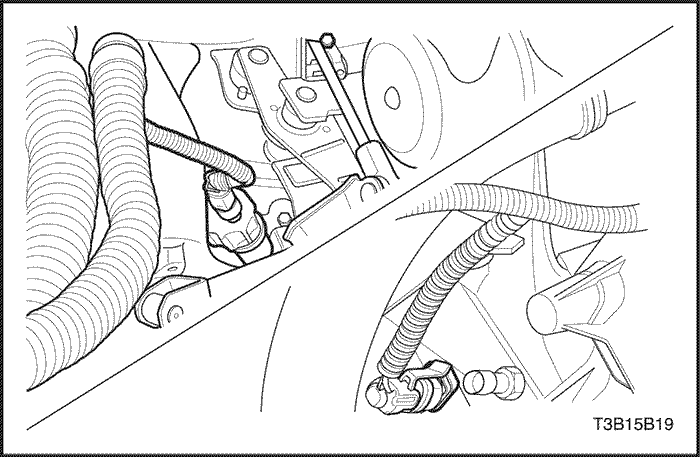

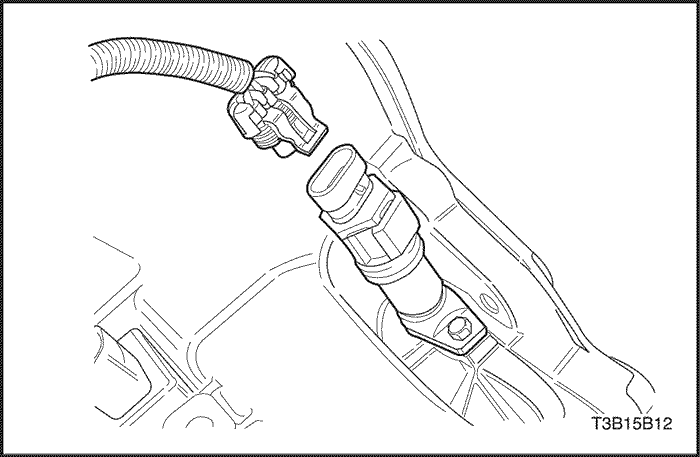

- Disconnect the speedometer speed sensor electrical connector.

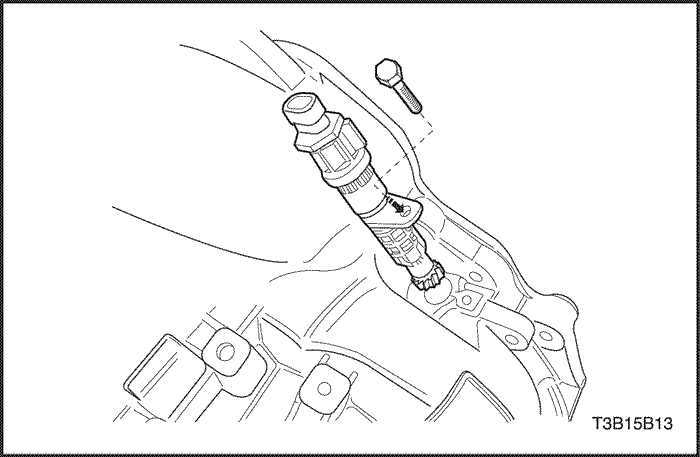

- Remove the speedometer housing retaining bolt.

- Remove the speedometer-driven gear and the speedometer housing.

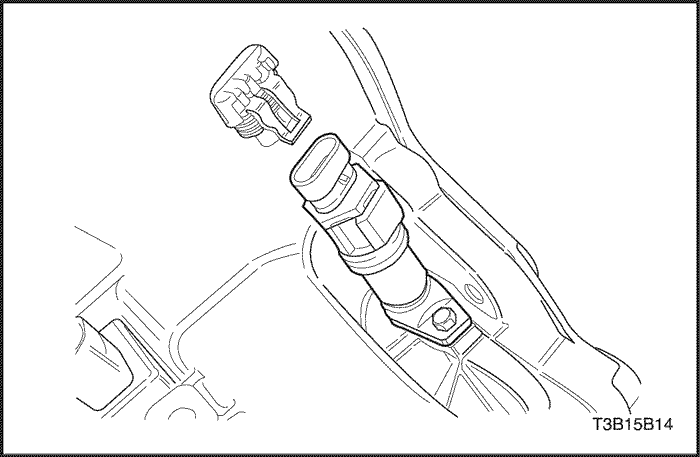

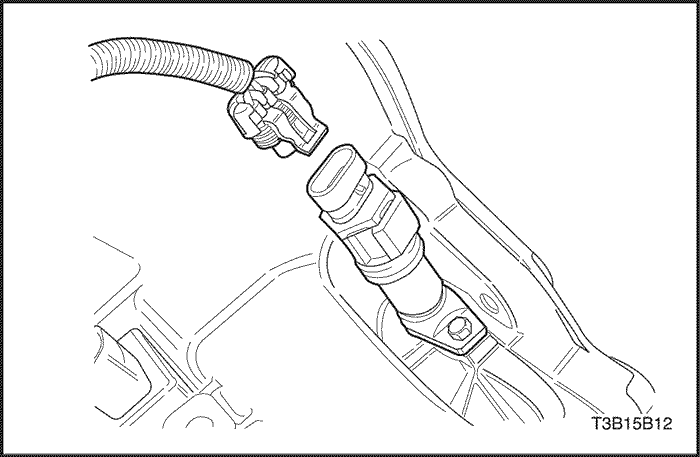

Installation Procedure

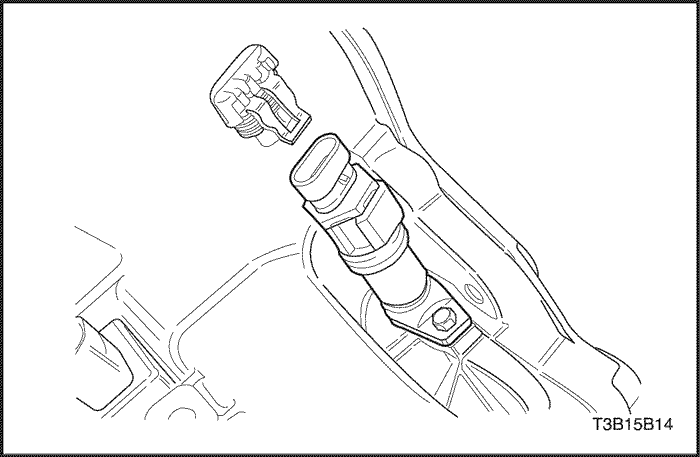

- Coat the O-ring with petroleum jelly.

- Install the speedometer-driven gear and the speedometer housing.

- Install the speedometer housing retaining bolt.

Tighten

Tighten the speedometer housing retaining bolt to 4 N•m (35 lb-in).

- Connect the speedometer speed sensor electrical connector.

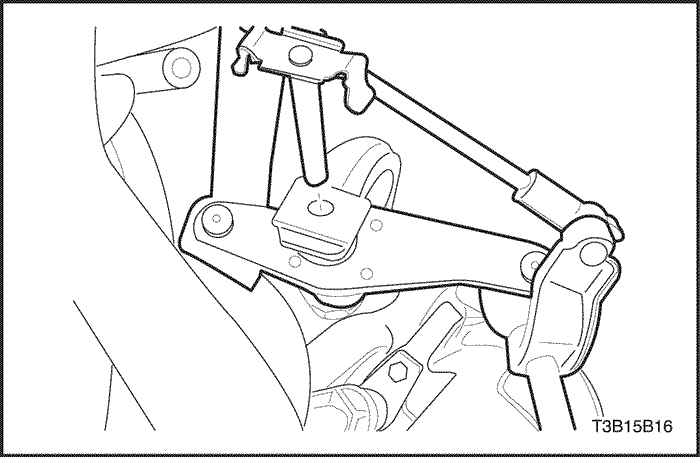

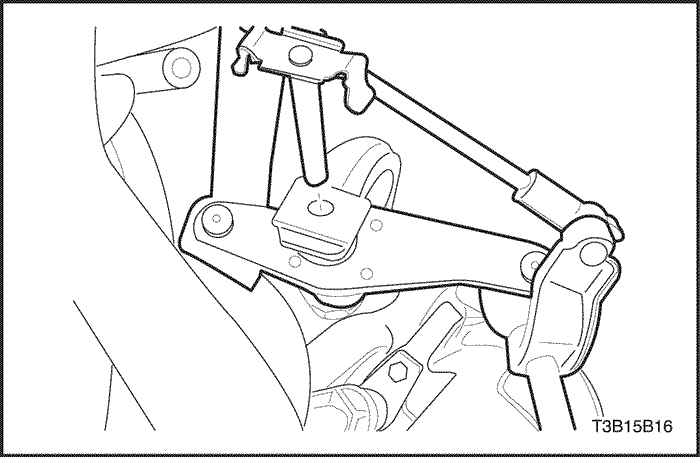

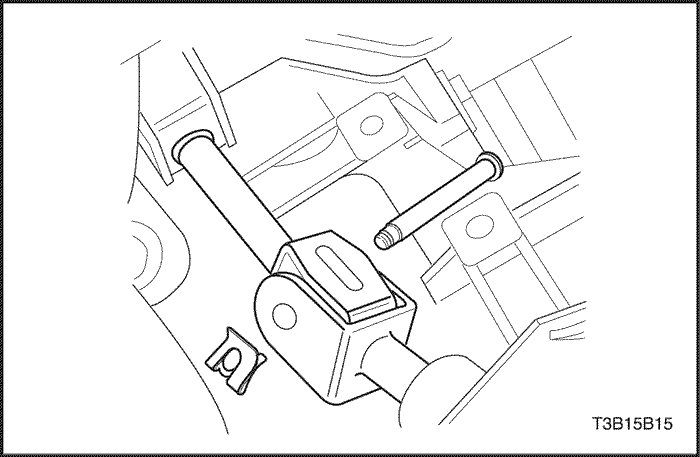

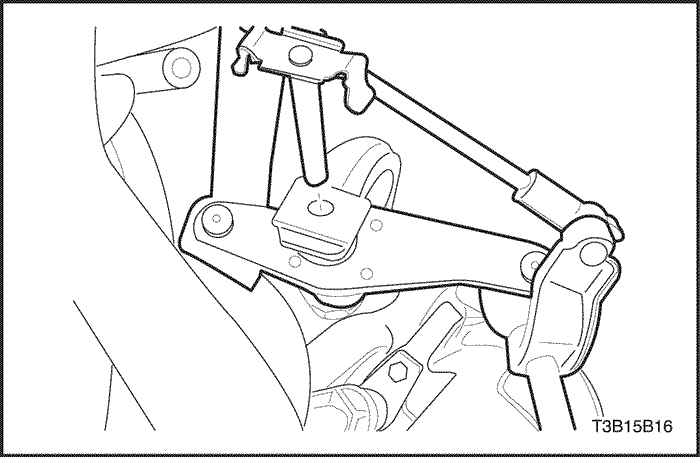

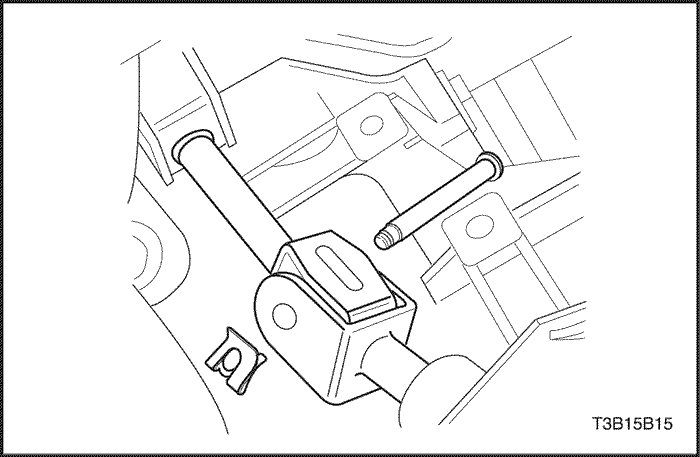

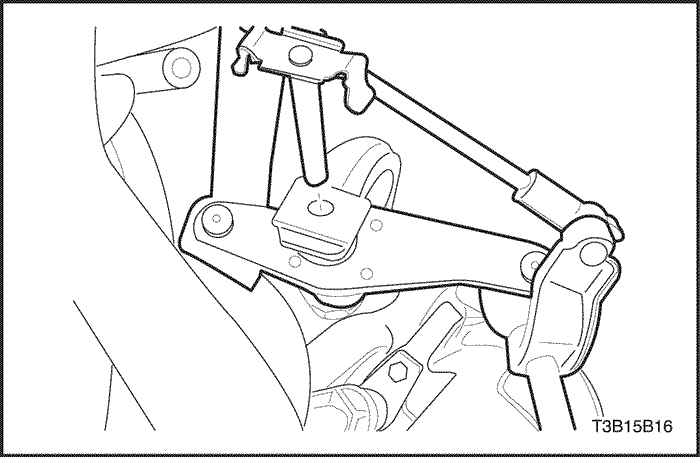

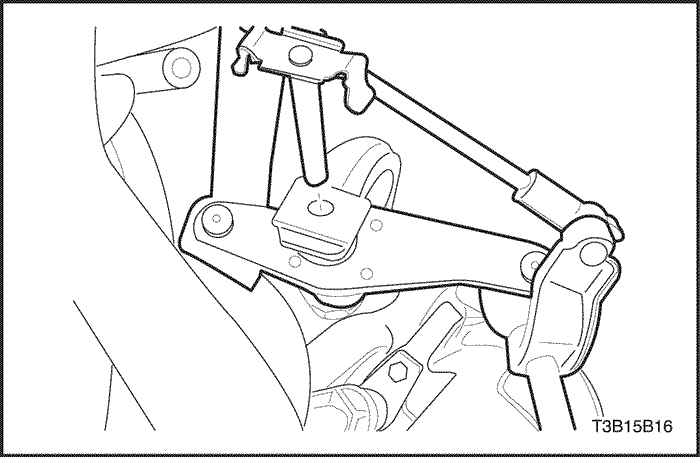

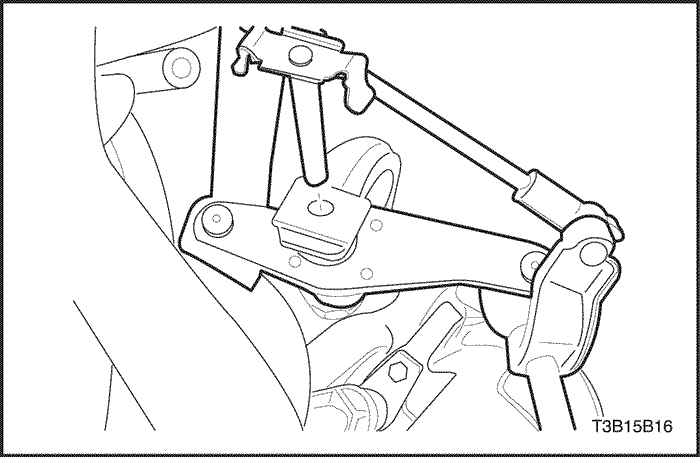

Shift Linkage Assembly

Removal Procedure

- Disconnect the negative battery cable.

- Remove the rod clamp. Refer to "Shift Linkage Adjustment" in this section.

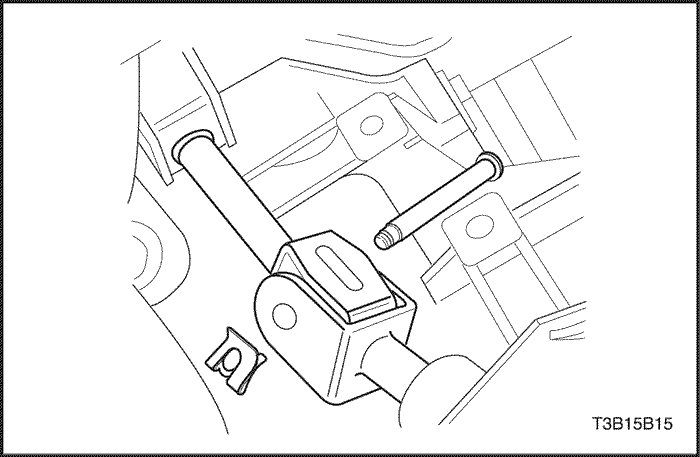

- Remove the clip and the bolt from universal joint.

- Separate the universal joint from the transaxle.

- Remove the fixing shaft pin and separate the linkage connection part from the transaxle rear mounting bracket.

- Remove the shift linkage assembly.

Installation Procedure

- Install the shift linkage assembly.

- Install the fixing shaft pin and connect the linkage connection part to the transaxle rear mounting bracket.

- Install the universal joint to the transaxle.

- Install the clip and the bolt from universal joint.

- Install the rod clamp. Refer to "Shift Linkage Adjustment" in this section.

- Adjust the shift linkage. Refer to "Shift Linkage Adjustment" in this section.

- Connect the negative battery cable.

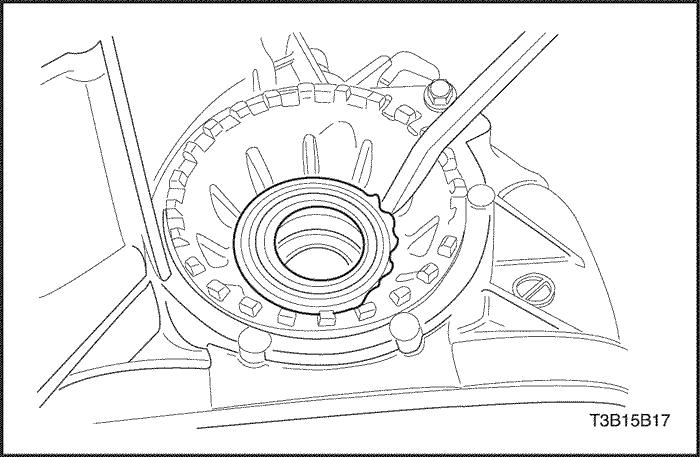

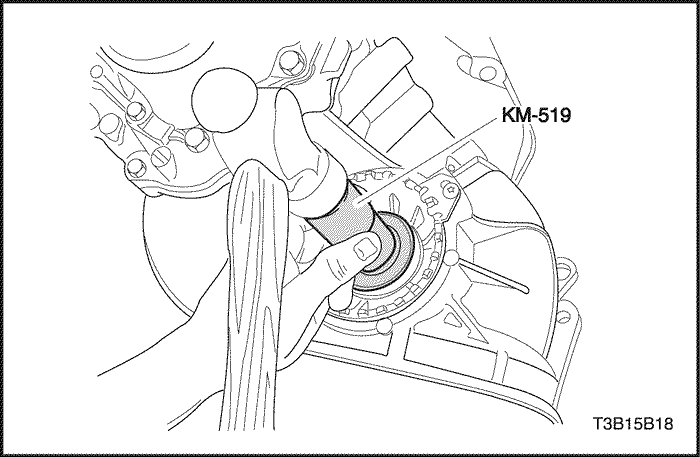

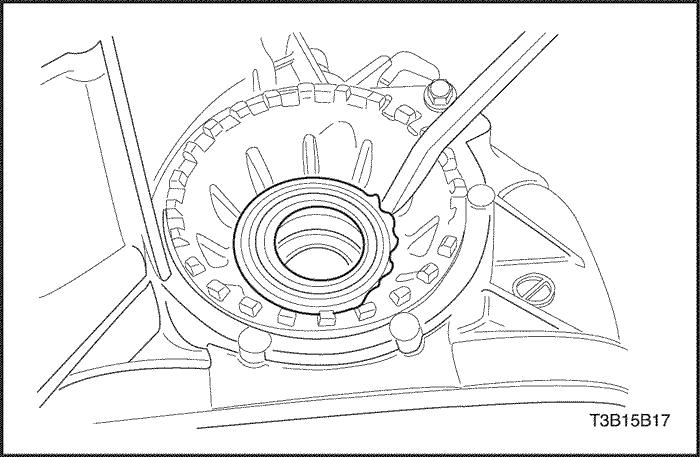

Drive Axle Seal

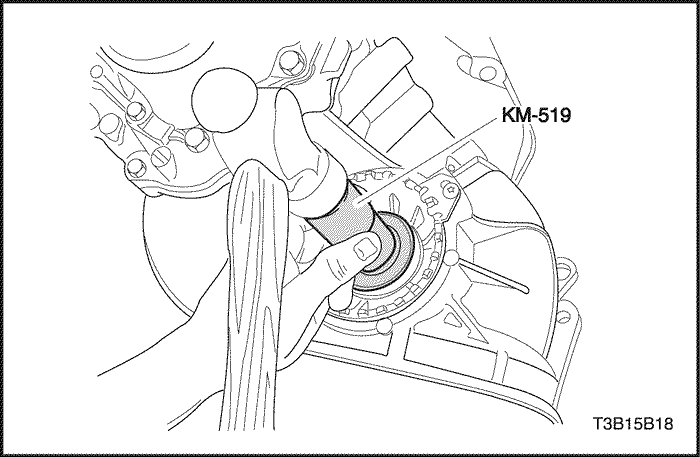

Tools Required

Removal Procedure

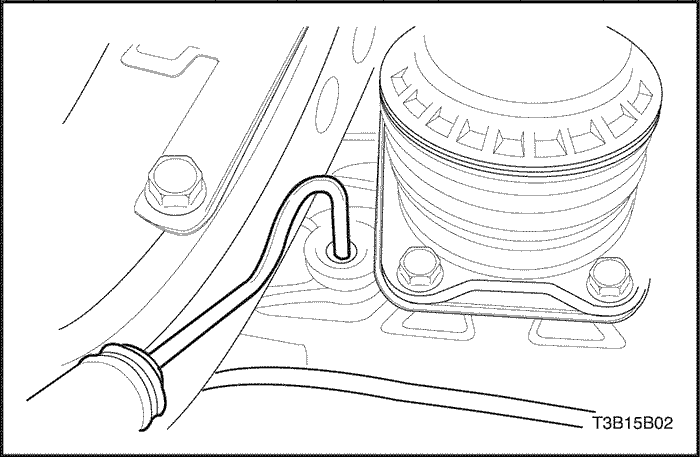

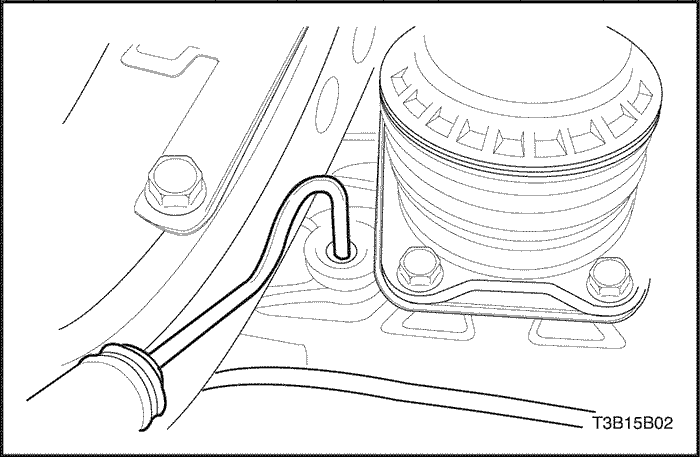

Notice : Do not damage the bearing adjusting ring with the pry bar.

- Remove the drive axle from the transaxle. Refer to Section 3B, Manual Transaxle Drive Axle.

- Remove the drive axle seal by lifting the outer lip of the seal with a pry bar.

Installation Procedure

- Install the new drive axle seal using the ring installer KM-519 and a hammer.

- Coat the seal lip with the transaxle fluid.

- Install the drive. Refer to Section 3B, Manual Transaxle Drive Axle.

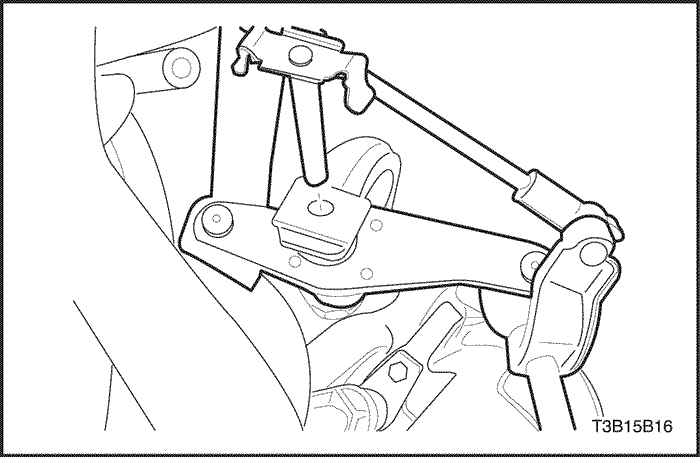

Transaxle Assembly

Tools Required

J-28467-B Engine Support Fixture

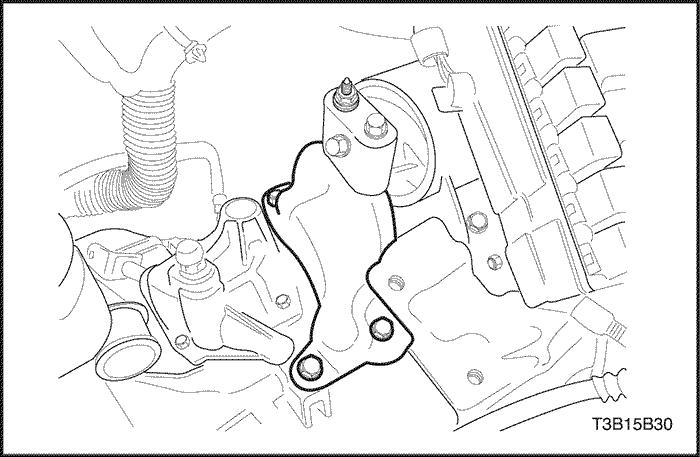

Removal Procedure

- Install the engine support fixture J-28467-B.

- Remove the battery and battery tray. Refer to Section 1E, Engine Electrical.

- Remove the shift linkage assembly. Refer to "Shift Linkage Adjustment" in this section.

- Remove the drive axle shaft. Refer to Section 3A, Automatic Transaxle Drive Axle.

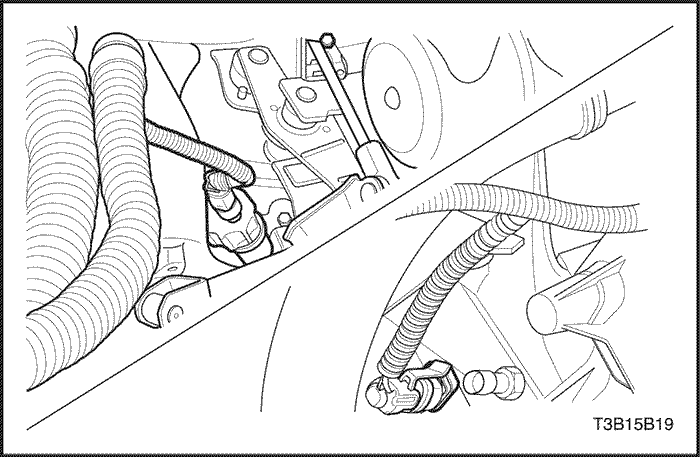

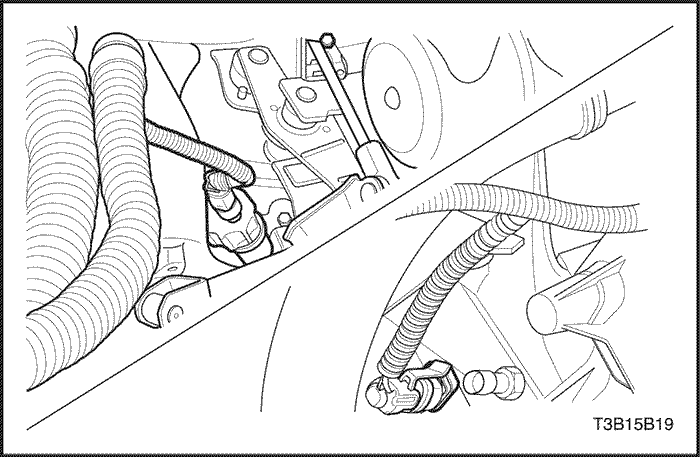

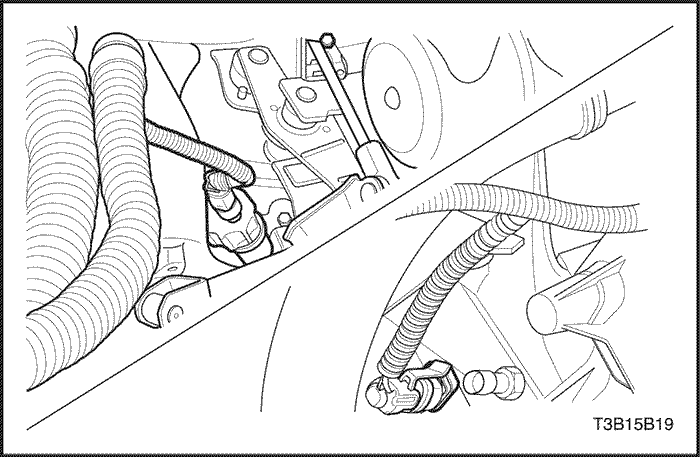

- Disconnect the backup lamp switch electrical connector.

- Disconnect the speedometer speed sensor electrical connector.

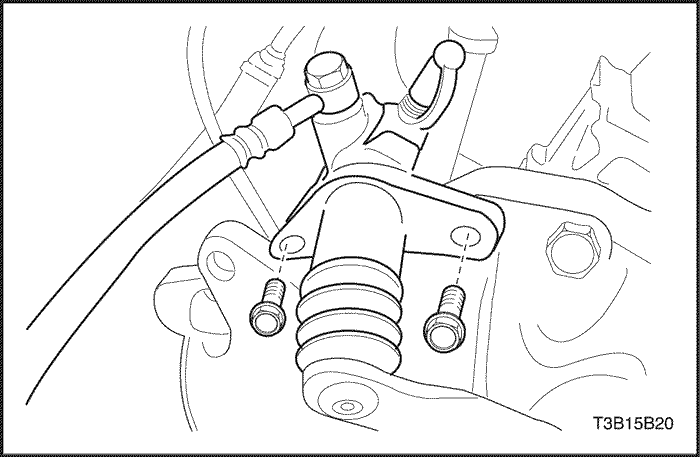

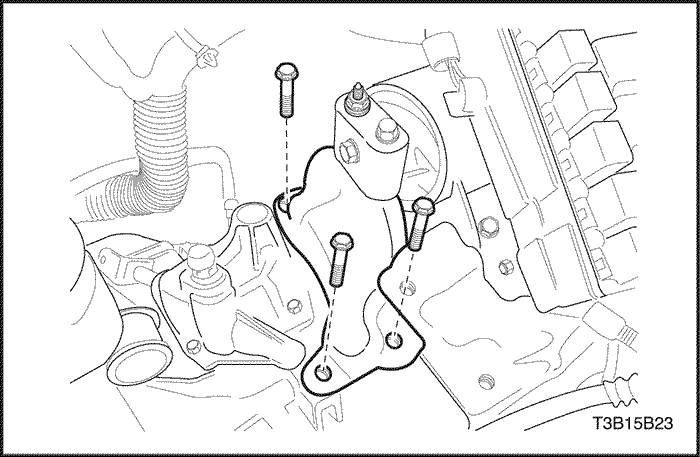

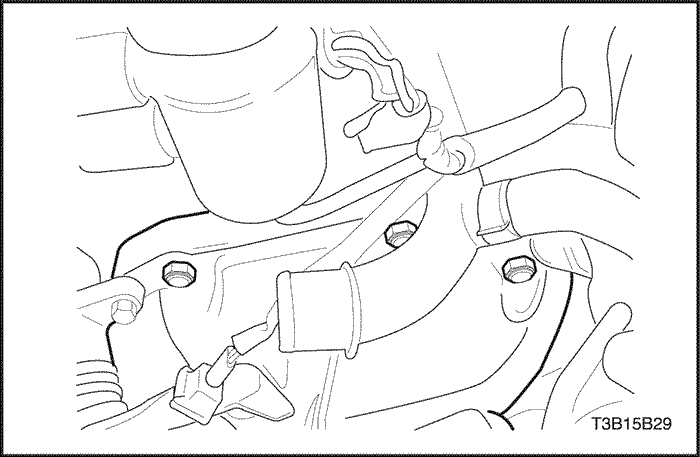

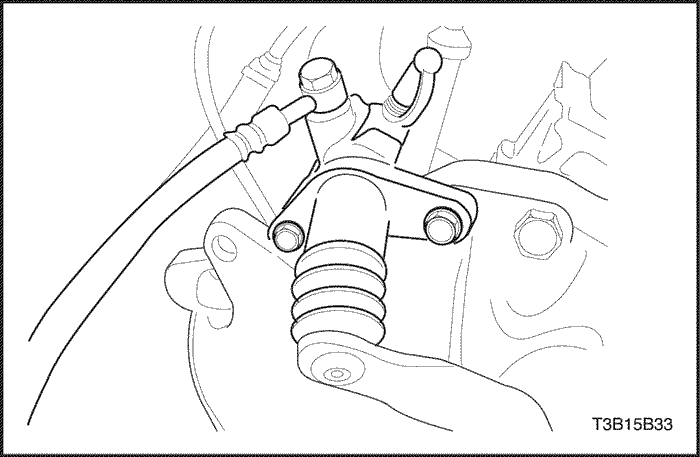

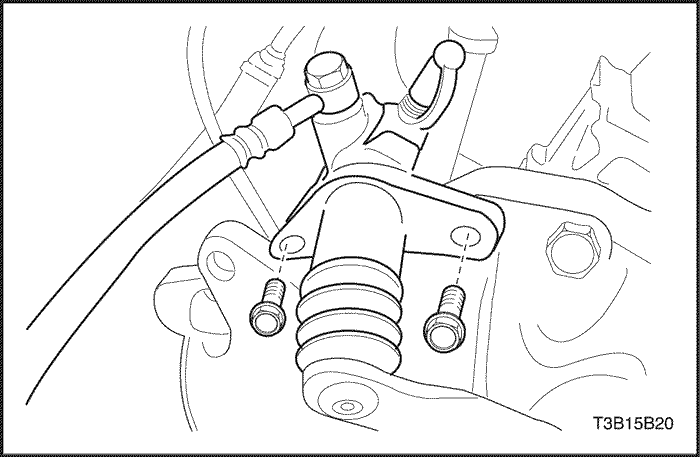

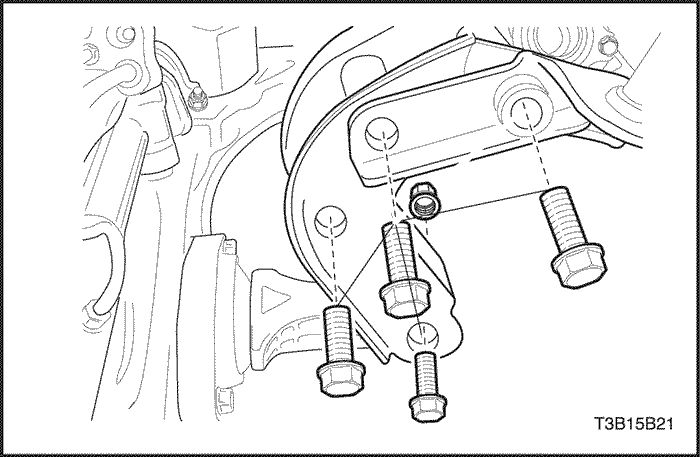

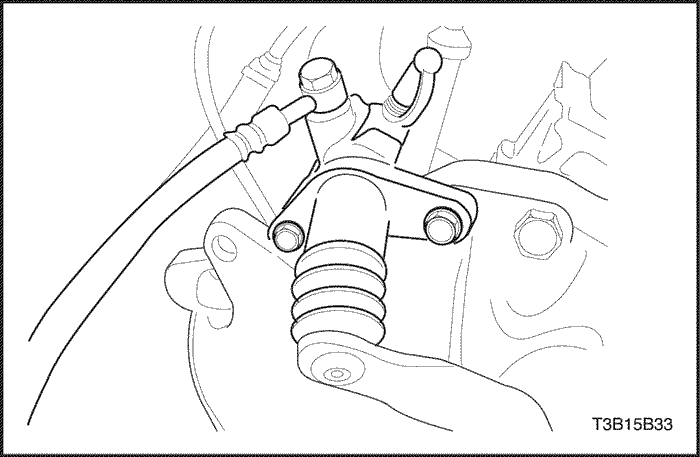

- Remove the clutch release cylinder retaining bolts and the clutch release cylinder.

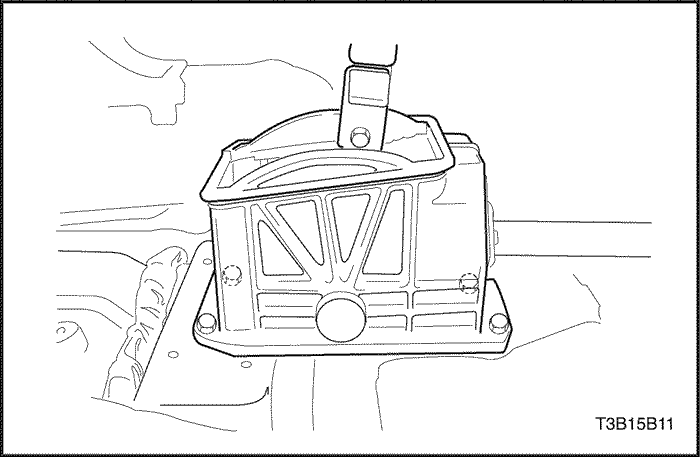

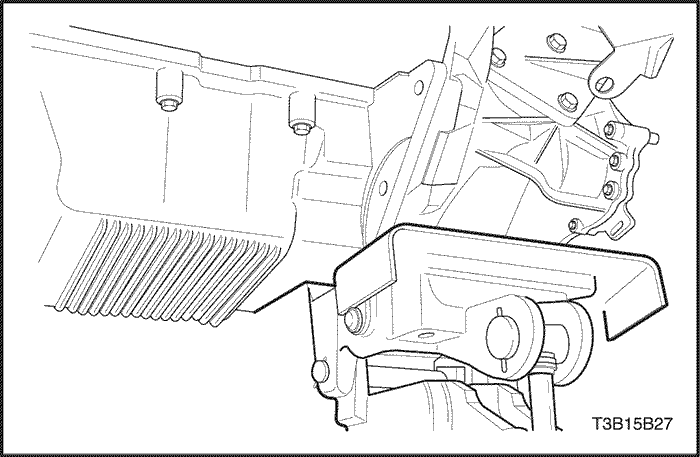

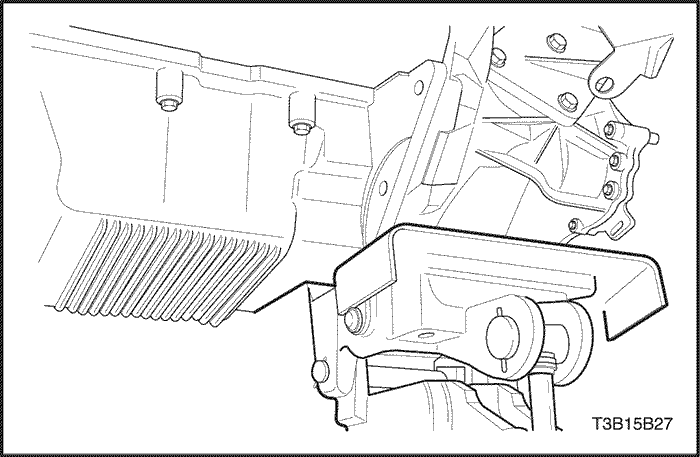

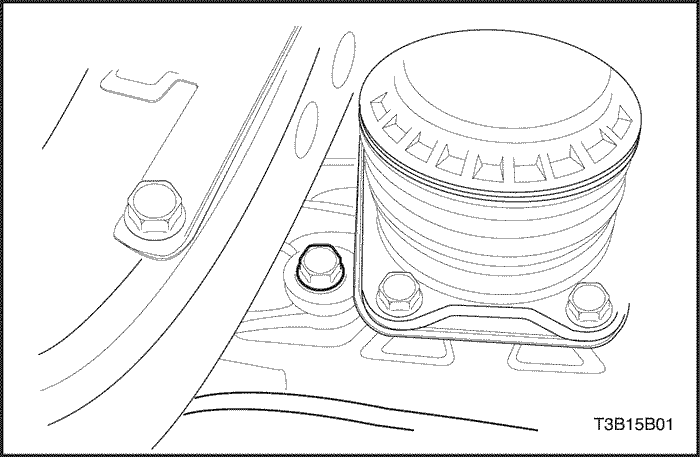

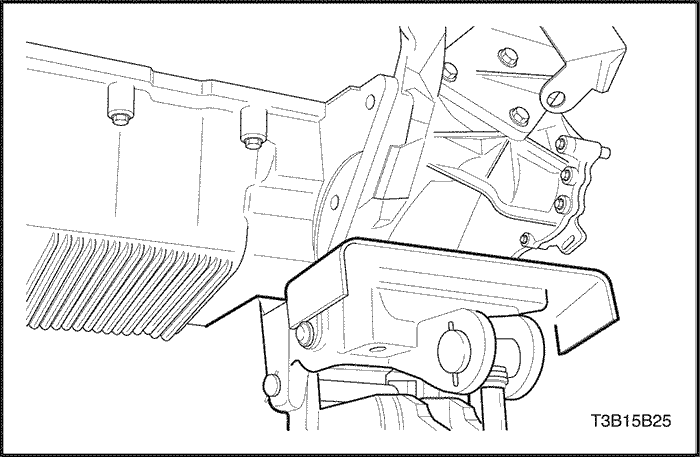

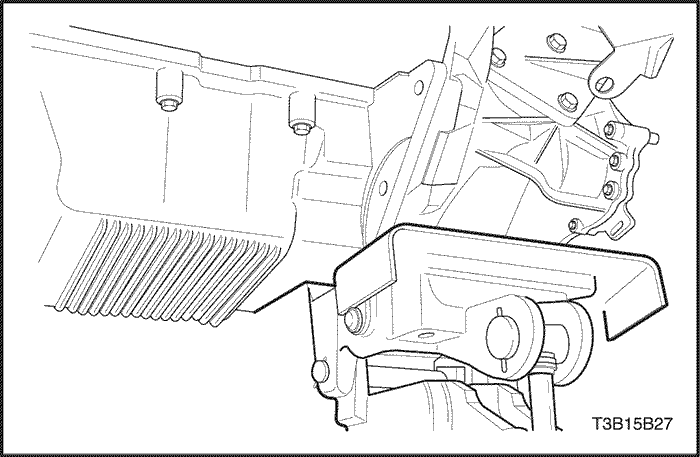

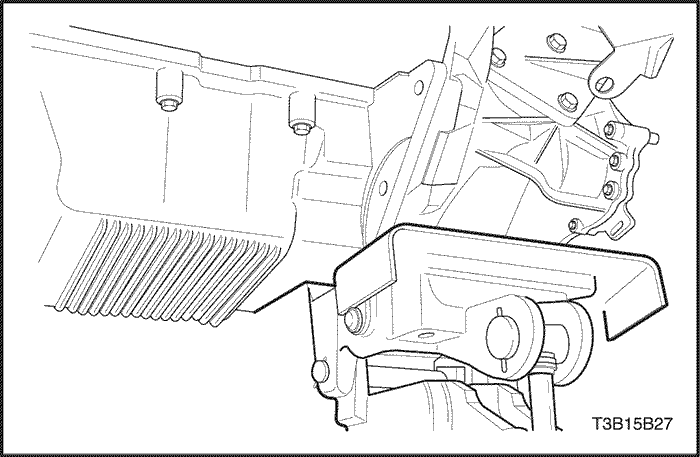

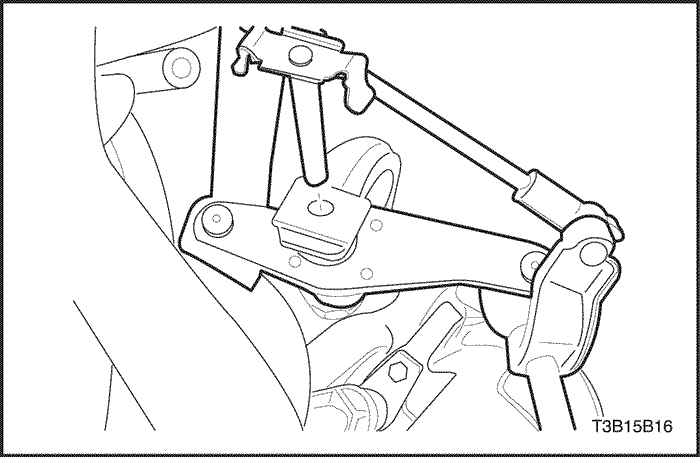

- Remove the damping block connection nut and bolt.

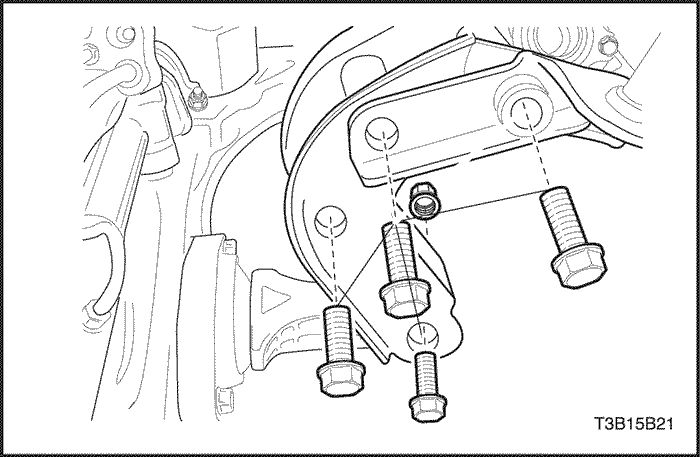

- Remove the three rear mounting bracket bolts.

- Remove the rear mounting bracket from the transaxle.

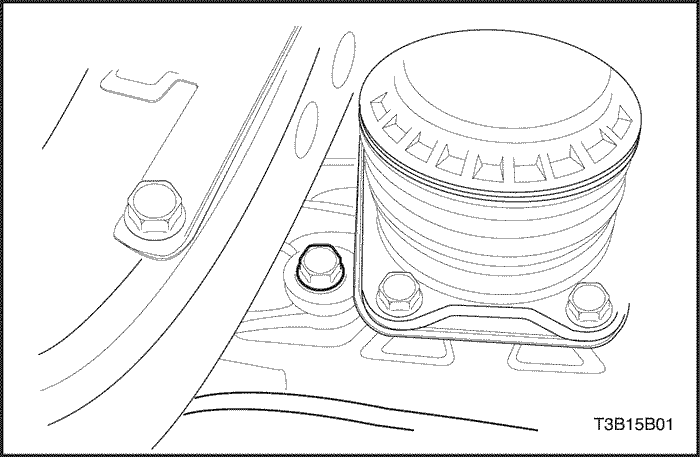

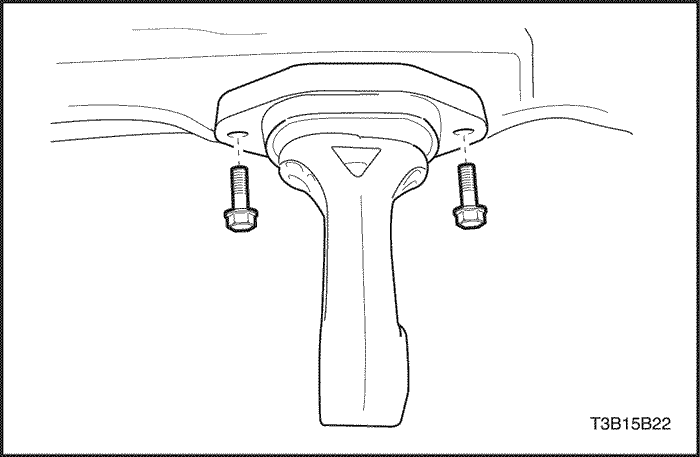

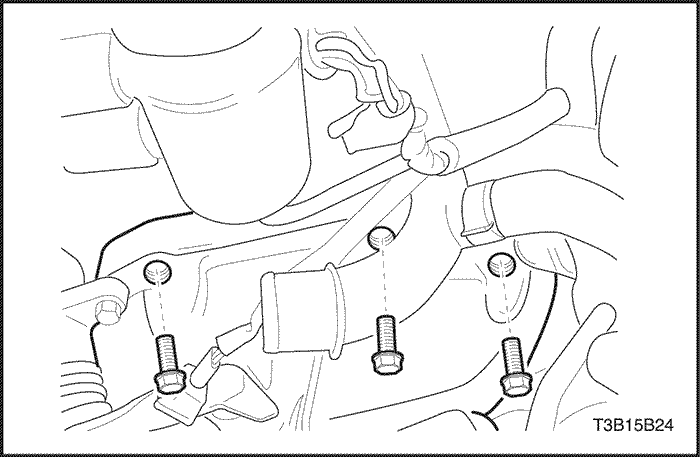

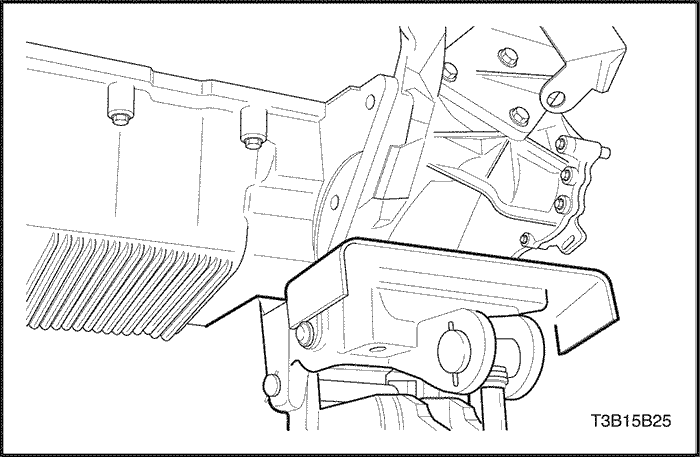

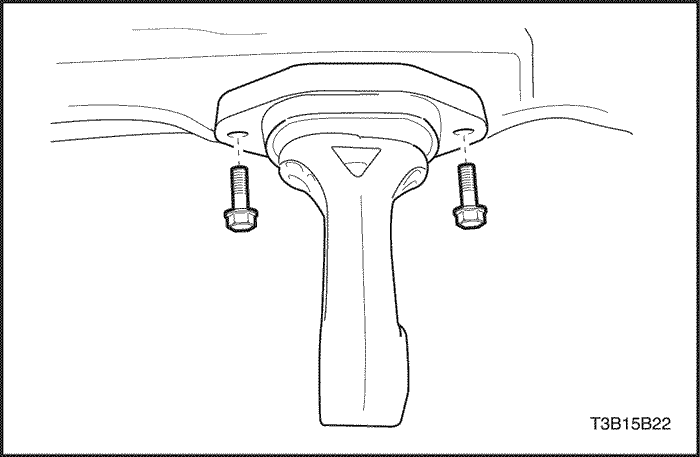

- Remove the two rear damping block retaining bolts.

- Remove the rear damping block from the front cross member.

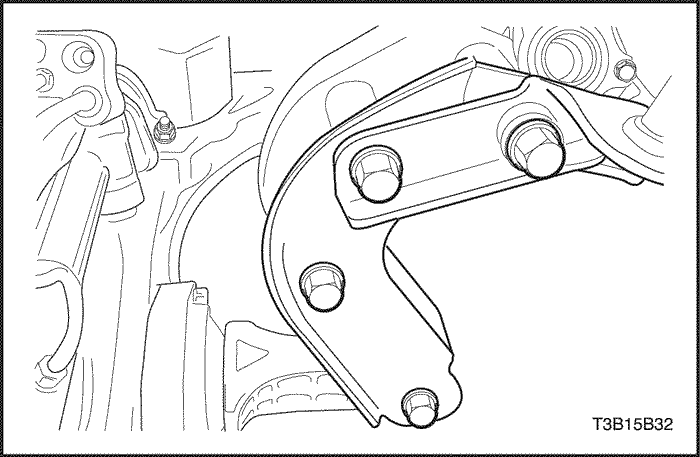

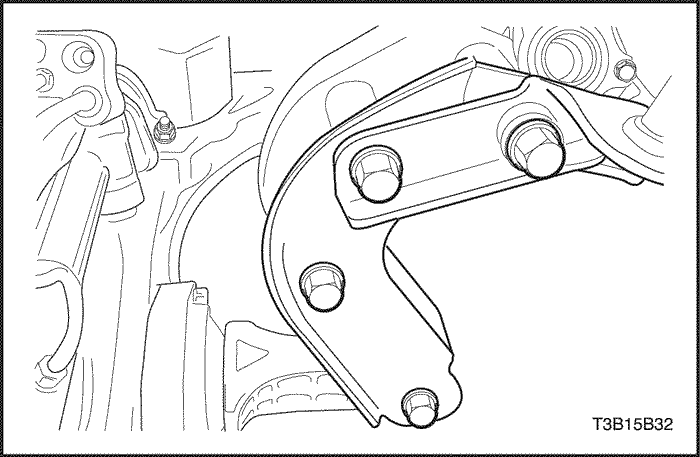

- Remove the two cage retaining bolts.

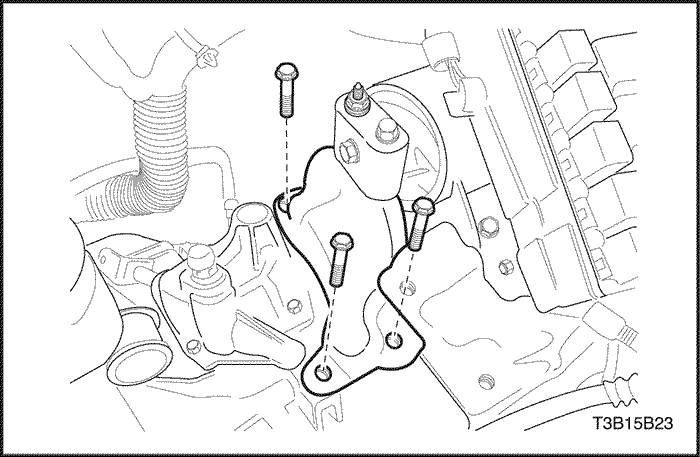

- Remove the three transaxle upper mounting bracket bolts.

- Remove the upper mounting bracket and cage.

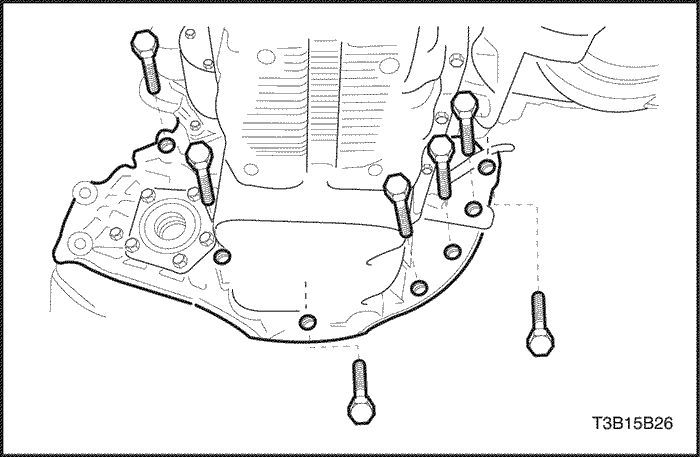

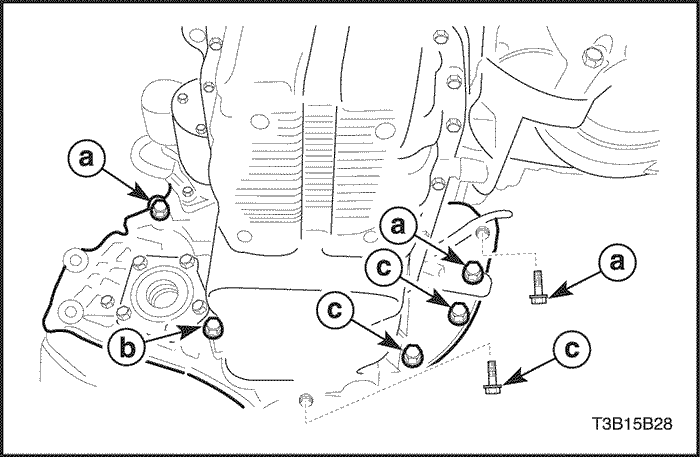

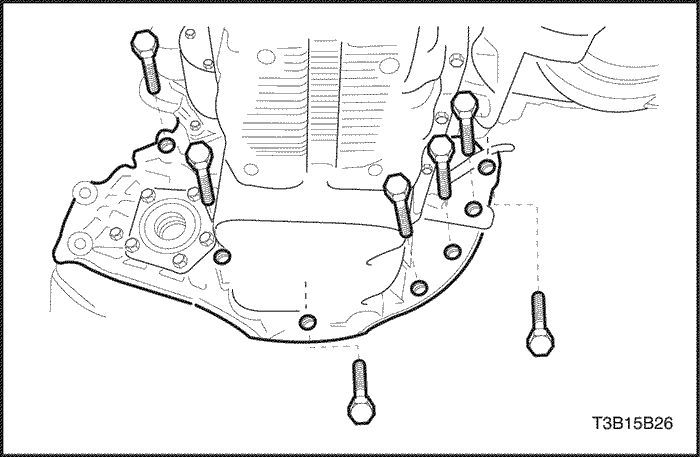

- Remove the three transaxle upper retaining bolts.

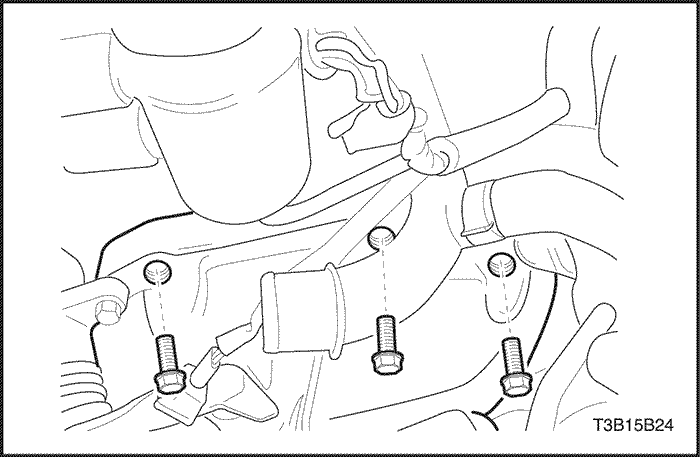

- Support the transaxle with a transaxle support jack.

- Remove the seven transaxle lower retaining bolts.

- Remove the transaxle.

Notice : Rest the transaxle only in an upright position.

- Slide the transaxle sideways away from the engine block.

- Lower the transaxle.

Installation Procedure

- Support the transaxle with a transaxle support jack.

- Install the transaxle by inserting the transaxle input shaft into the clutch disc and sliding the transaxle sideways into the engine block.

- Install the seven transaxle lower retaining bolts.

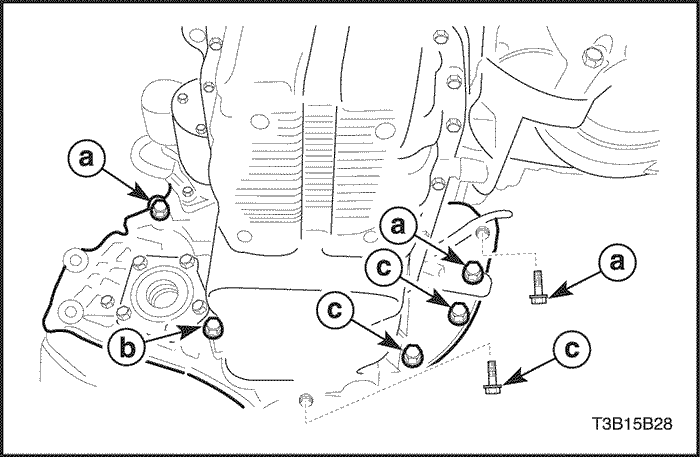

Tighten

Tighten the transaxle lower retaining bolts(a) to 73 N•m ( 54 lb-ft ).

Tighten the transaxle lower retaining bolt(b) to 31 N•m ( 23 lb-ft ).

Tighten the transaxle lower retaining bolts(c) to 21 N•m ( 15 lb-ft ).

- Install the three transaxle upper retaining bolts.

Tighten

Tighten the transaxle upper retaining bolts to 73 N•m (54 lb-ft ).

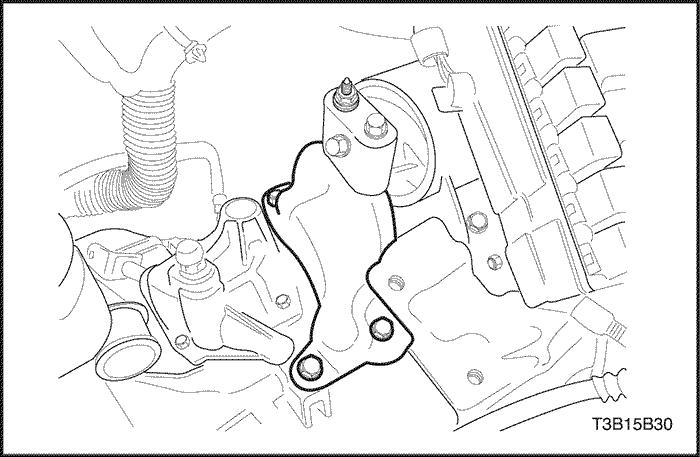

- Install the cage retaining bolt and cage.

- Install the three transaxle upper mounting bracket bolts and bracket.

Tighten

Tighten the transaxle upper mounting bracket bolts to 60 N•m (44 lb-ft ).

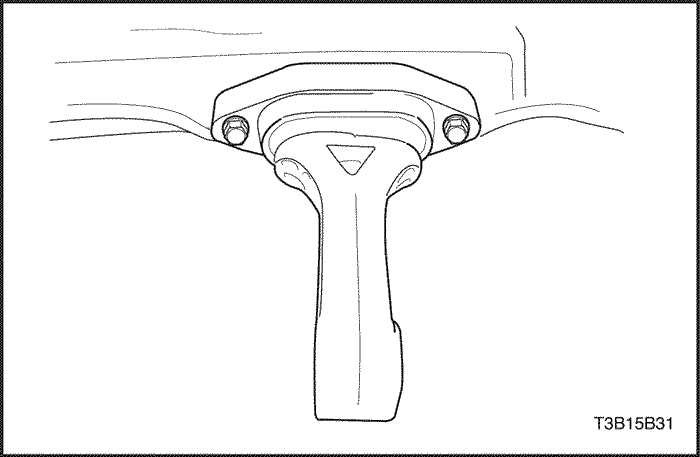

- Install the two rear damping block retaining bolts.

Tighten

Tighten the rear damping block retaining bolts to 55 N•m (41 lb-ft ).

- Install the rear damping block from the front cross member.

- Install the three rear mounting bracket bolts and the bracket.

Tighten

Tighten the rear mounting bracket bolts to 80 N•m (59 lb-ft ).

- Install the damping block connection nut and bolt.

Tighten

Tighten the damping block connection nut and bolt to 80 N•m (59 lb-ft ).

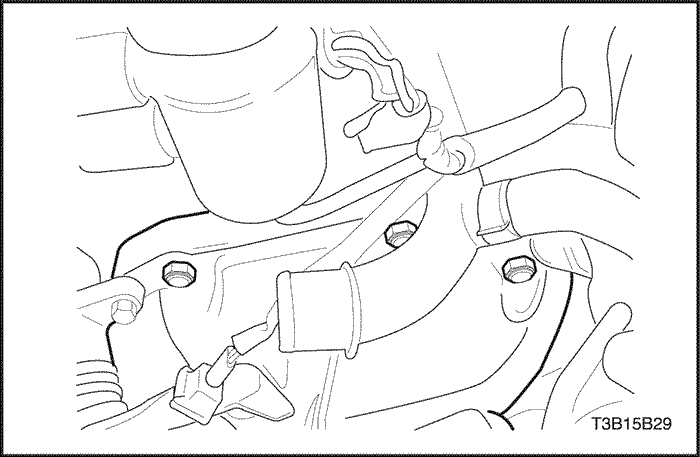

- Install the clutch release cylinder retaining bolts and the clutch release cylinder.

Tighten

Tighten the clutch release cylinder retaining bolts to 20 N•m (15 lb-ft ).

- Connect the speedometer speed sensor electrical connector.

- Connect the backup lamp switch electrical connector.

- Remove the engine support fixture J-28467-B.

- Install the drive axle shaft. Refer to Section 3A, Automatic Transaxle Drive Axle.

- Install the shift linkage assembly. Refer to "Shift Linkage Assembly" in this section.

- Install the battery and battery tray. Refer to Section 1E, Engine Electrical.

- Inspect the fluid level. Refer to "Checking Fluid Level" in this section.

| |  | |

| © Copyright Chevrolet Europe. All rights reserved |