SECTION

7

ANNEX

1. RECEIVING

INSPECTION

When receiving a new vehicle, Dealer is to inspect

it immediately for damage, obvious missing or incorrect part and

/ or options. This inspection is to be completed before

accepting the receipt of vehicle.

- 1) Inspection of new

vehicle

- The

inspection of each received for possible damage is very

important because new vehicles have usually traveled a

long distance from the factory to the Dealer, often

passing through several methods of

transportation.

- The following should be included

in the inspection;

- a. Walk around inspection of

the exterior and visible areas of the vehicles

undercarriage

- b. Under hood

inspection

- c. Trunk or Cargo area inspection,

including all parts and/or options normally stored or

transported in this area

- d. Interior inspection,

including all trim panels, headlines carpets, and

upholstery.

- 2) Transportation

damage

- GMDAT's (GM

Daewoo Auto & Technology Co., Ltd.) responsibility

for damages and / or shortages extends only to the

passage of vehicle through the ship's rail at the port

of shipment. Thereafter such responsibility shall be for

the carrier and / or insurance company until the

delivery documents is signed by the Dealer's

representative as having received the vehicles either in

good order or with exceptions noted.

- Any

transportation damage including stolen or missing part

should be noted in detail and reported to the insurance

company and the carrier immediately after receipt and

inspection of new vehicles.

- 3) Missing or

incorrect parts and production shortages

- If any

missing or incorrect parts and options are discovered

while receiving inspection of new vehicles, claims have

to be made to whomever is responsible, either to the

carrier / insurance company or to GMDAT.

- In case

GMDAT is responsible for any missing or incorrect parts

and production shortages i. e. those were omitted in

production of the vehicle the Dealer may request

compensation for the costs incurred by correction of

such discrepancies under warranty.

- Claims for

missing parts, noticeable at the time of vehicle

inspection, such as audio equipment, antenna, spare tire

and wheel, wheel cover, jack assembly, tools and so on,

which are to be considered as having been removed during

transit, are not reimbursable under warranty provisions

of this manual. Such claims rather should be presented

to the representative of the carrier to the insurance

company.

2. DIRECTION FOR THE USE OF

HY-600 TRANSIT COATING REMOVER IN A HAND WASH

OPERATION

Material Required: One bottle (0.8 L) of transit

coating remover per vehicle

Equipment Required: Bucket, wash mitt, safety

glasses, rubber boots and glove, hose.

The removal operation should be performed in a well

ventilated and shaded area to prevent rapid evaporation of the

remover solution and to reduce the likelihood of water spotting

on the completed vehicle. The area must have drainage facilities

and be located away from grass and plants biodegradable. The

removal steps for transit coating are as follows;

- 1) Pre-rinse the entire surface

of the vehicle with water to remove accumulated particle and

/ or other debris from the coating surface to prevent

scratching the surface finish.

- 2) Mix HY-600 water

detergent transit coating remover at either 1:2 (which

equals 1 bottle of remover to one gallon of water) or 1:4

(which equals 1 bottle of remover to one and half gallon of

water).

- 3) Apply the diluted remover solution with a

wash mitt agitating as you would normally wash a vehicle.

Wash the vehicle one section (roof, hood, deck lid, etc.) at

a time keeping the remover wet while in contact with the

coating.

- 4) Allow the HY-600 to remain on the

vehicle for approximately 1-2 minutes to break down the

coating via chemical action.

Note : Do not allow the remover to dry.

Continuously agitate the vehicle surface during the

removal process (approximately 1-2 minutes) in order to

prevent surface drying.

- 5) Thoroughly rinse the entire

vehicle with clean tap water to remove the solubilized

coating and remover product.

- 6) Using a towel or

chamois, wipe the vehicle dry to prevent water

spots.

- 7) Inspect the vehicle for areas where the

protective transit coating may not have been removed. Spot

removal can be achieved by applying a small amount of HY-600

diluted 1 to 1 up 1 to 4 with tap water and wiping the area

with a clean dry cloth.

Notice :

- 1) The setting time of 1-2

minutes is very important to remove the shipping

wax.

- 2) If the remaining wax was found after

this procedure, apply the transit coating remover

without dilution on these

areas.

3. STORAGE AND

MAINTENANCE OF NEW VEHICLE IN EXTREMELY HOT AND HUMID

LOCATIONS

DESCRIPTION:

The protection and maintenance of new

vehicles awaiting delivery to customer are the exclusive

responsibility of distributor. Regular maintenance is necessary

to prevent rust formation or environmental damage. Given belows

are the minimum maintenance guideline to be required during

storage of new vehicles in extremely hot and humid

locations.

- A. Storage

Location

- Vehicles

should be stored in a clean, dry, closed, roofed and

well ventilated area, if possible. When outdoor storage

is used, the followings should be considered as minimum

requirements.

- 1) The area should be well drained

and have a hard or paved surface.

- Recommendation

: Installation of CANOPY on the above area in order to

protect from the ultra violet rays of the sun and

contamination resulted from dust and fallout. (refer to

detail figure 1&2 on page 7-8 & 7-9.)

- 2)

The following locations should be avoided :

- –Low area where flood

waters can damage vehicles.

- –Location adjacent

to factories emitting exhaust air which is corrosive or

laden with dirt.

- –Location near body

shop.

- –Storage under trees, where damage to

finishes may result from tree sap and/or bird dropping.

- Coastal area to protect body from salt

contamination.

- 3) If possible, vehicle

should be parked on a level surface.

- B.

Storage Preparation

- Certain precautions must be

taken when placing a vehicle in storage as following

recommendations;

- 1) Body and exterior parts

protection.

- Body should be protected from damage

such as discoloration of chrome or bright finished trim

and painted surfaces. It can be caused by deposits of

dirt, grease, oil or other injurious materials. To

protect body, following operations are

required.

- –Carefully wash the underbody and

chassis to remove all injurious materials such as

grease, oil, tar or mud deposits that may have

accumulated in transit.

- Carefully check the

painted surface and touch up all exposed primed or law

metal surface to prevent rust

formation.

Note : Such touch up are to be considered

as the distributor normal pre-delivery

responsibility.

- –For the preservation of

the exterior, wax is applied to protect the vehicle

during transportation against external chemical

influences. New preservation should be carried out, if

necessary.

- 2)Interior

- If the

vehicle is exposed to strong sun light, cover the seat,

trim, instruments, etc with a cloth, or cover the window

with some kind of sun shade or shield. (In order to

prevent color fading, detonation, bubble and peeling

off)

- Keep the ventilation system open(In order

to prevent some damage of interior parts due to high

temperature), open the window a little(2~3cm) especially

at the very hot weather

condition.

Caution : If the ultrasonic

interior space protection system is installed in the

vehicle, keep the

follows.

- –When opertating ultrasonic

interior space protection system by transmitter,

you must operate it after closing windows and

sunloof(If equipped).If not, ultrasonic interior

space protection system may give the alarm by

malfunction.

- –When locking the car on

condition that windows or sunloof(If equipped)

are opened, you must use only the key to lock

the car. Anti-theft mode could not be armed by a

key locking doors without

transmitter.

Keep the all windows open at a week

intervals.

Open four windows

fully

- 3) Engine

- If

vehicles run for short intervals (5 minutes or less) at

dealershop or body builders, condensation may form

within the engine. To avoid this possibility, it is

recommended that the engine should run at approximately

1,200rpm until the engine temperature reaches normal

condition on a weekly basis. This will evaporate any

condensation that may have been

present.

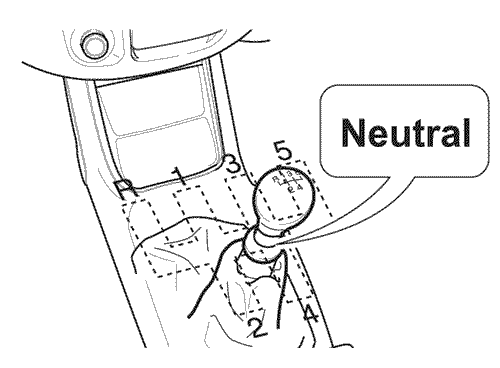

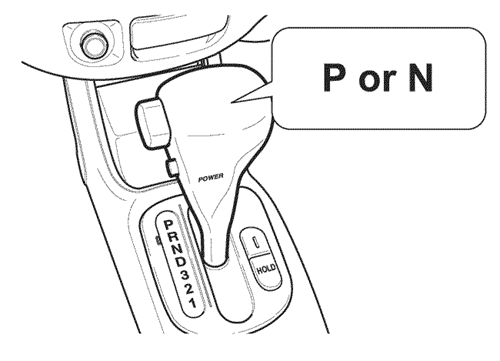

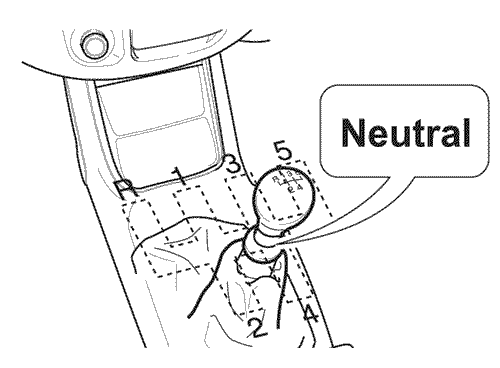

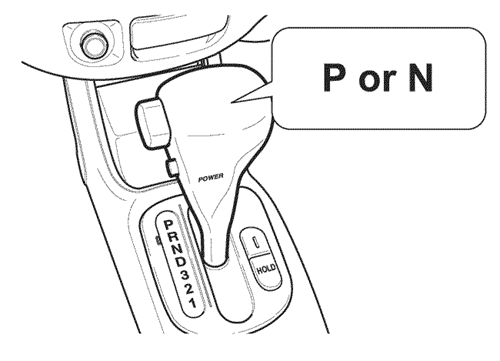

Note : Repeat this operation at least

once a week while the vehicle is in storage and shift

all steps of transmission during engine

running.

- 4)Battery

- It is the

distributor's responsibility to ensure that they are

protected by the maintenance of a full charge and/or

avoidance of storage in a hot weather

area.

- Check whether the battery is discharged or

not at 15-day intervals and recharge the battery as

necessary.

- Check the battery terminals for

corrosion(a white or bluish powder) with disconnecting

the negative(-) cable and remove it with a solution of

baking soda and water if necessary.

- And then

coat the terminals with petroleum jelly.

- Keep

the battery cable connection and main fuses

disconnected.

- 5)Brake

- –Do not

apply the parking brake.

- –Leave the service brake

also in fully released position.

- 6) Tire

- Inflate the

tires as recommended pressures. Keep air pressure in

tires a higher than it is recommended during long stock

for preventing deformation and change tire location by

moving vehicle. Periodically rotate tires to change the

ground contact positions of the tires. Check for damage

or crack.

- 7) Air

Conditioner

- Operate the air conditioner for a

few minutes at the engine idle speed the circulation of

compressor oil through air conditioner system, thus it

prevents the seizure of compressor

components.

- 8) MIscellaneous

Precautions

- –Make sure that all linkage, lever,

pin and cables under the hood and under the vehicles are

covered with grease to prevent rust

formation.

- –Thoroughly lubricate the chassis,

especially rear inside corner of engine hood, wheel

bolt, wheel cap, brake caliper and suspension to prevent

rust formation.

- –All vehicles should be moved 10

meters or more at every 21 days to provide a lube

coating to the vital working parts and prevent

corrosion.

- –Because effectiveness of protective

wax is limited to 6 months, when storaging more than 3

months, remove shipping wax coating and then respray

protective wax. (paraffine wax)

- –In heavy snow

season, move the vehicle to the safety area. Do not

store the vehicles in the CANOPY.

The canopy may collapse due to heavy

snow, resulting in the vehicle damage.

EXAMPLE OF CANOPY